19 Dec 2025

// PRESS RELEASE

21 Nov 2025

// PRESS RELEASE

29 Sep 2025

// PRESS RELEASE

KEY SERVICES

KEY SERVICES

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

About

Industry Trade Show

Lotte New York Palace

23-26 March, 2026

Industry Trade Show

Attending

21-23 April, 2026

Chemspec EuropeChemspec Europe

Industry Trade Show

Attending

06-07 May, 2026

CONTACT DETAILS

Events

Webinars & Exhibitions

Industry Trade Show

Lotte New York Palace

23-26 March, 2026

Industry Trade Show

Attending

21-23 April, 2026

Chemspec EuropeChemspec Europe

Industry Trade Show

Attending

06-07 May, 2026

https://www.pharmacompass.com/speak-pharma/we-were-able-to-secure-our-crucial-supplies-throughout-the-pandemic-speakpharma-with-teva-api

CORPORATE CONTENT #SupplierSpotlight

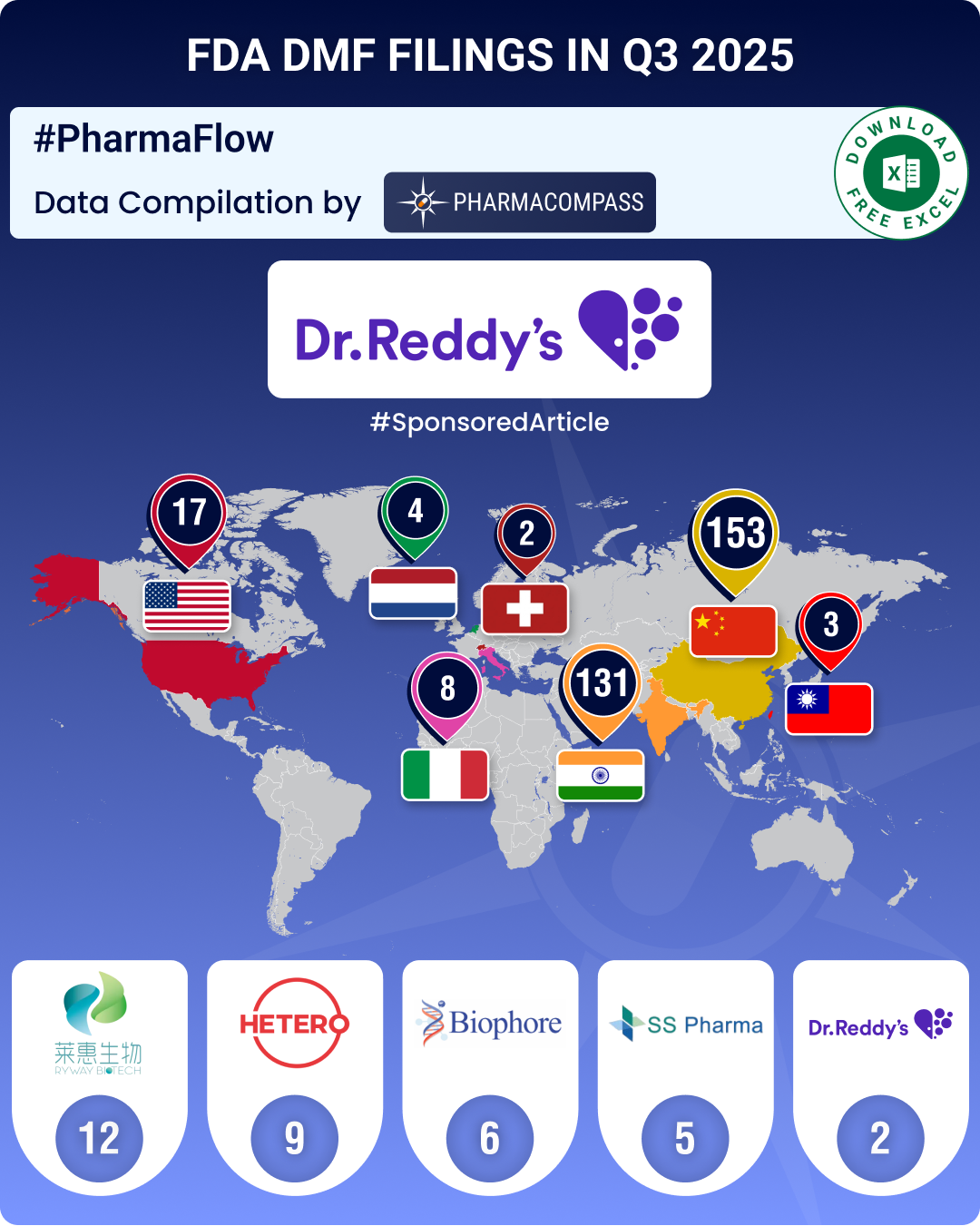

https://www.pharmacompass.com/radio-compass-blog/dmf-filings-rise-4-5-in-q3-2025-china-holds-lead-india-records-20-growth-in-submissions

https://www.pharmacompass.com/radio-compass-blog/cdmo-activity-tracker-veranova-carbogen-lead-adc-investments-axplora-polfa-tarchomin-famar-expand-european-footprint

19 Dec 2025

// PRESS RELEASE

https://tapi.com/knowledge-center/tapi-and-sagimet-biosciences-announce-global-license-agreement-for-innovative-forms-of-resmetirom-api-for-sagimets-fixed-dose-combination-program/

21 Nov 2025

// PRESS RELEASE

https://tapi.com/knowledge-center/tapi-and-antheia-announce-strategic-partnership-to-advance-commercialization-of-biosynthetic-pharmaceutical-ingredients/

29 Sep 2025

// PRESS RELEASE

https://tapi.com/knowledge-center/sustainable-by-design-how-tapi-is-building-a-greener-future-in-api-manufacturing/

25 Aug 2025

// PRESS RELEASE

https://tapi.com/knowledge-center/how-innovative-computational-tools-and-automation-are-reshaping-solid-form-development/

28 Jul 2025

// PRESS RELEASE

https://tapi.com/knowledge-center/driving-innovation-in-green-chemistry-redox-biocatalysis-allowing-full-stereocontrol/

21 Jul 2025

// PRESS RELEASE

https://tapi.com/knowledge-center/driving-bioprocess-innovation-how-tapi-is-transforming-fermentation-efficiency-with-smart-automation/

Click Us!

Click Us!

GDUFA

DMF Review : Reviewed

Rev. Date : 2012-11-29

Pay. Date : 2012-11-08

DMF Number : 7239

Submission : 1987-11-30

Status : Active

Type : II

Certificate Number : CEP 1997-077 - Rev 16

Issue Date : 2025-07-09

Type : Chemical

Substance Number : 1004

Status : Valid

Registration Number : 225MF10001

Registrant's Address : Plot No. 2G, 2H, 2I, Udyog Vihar, Greater Noida-201 308 (U.P.) India

Initial Date of Registration : 2013-01-15

Latest Date of Registration :

Date of Issue : 2025-04-24

Valid Till : 2028-05-25

Written Confirmation Number : WC-0002

Address of the Firm :

NDC Package Code : 15894-0022

Start Marketing Date : 2011-08-09

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (1kg/kg)

Marketing Category : BULK INGREDIENT

Registrant Name : Korea Unipharm Co., Ltd.

Registration Date : 2020-03-02

Registration Number : 20200302-209-J-279

Manufacturer Name : Teva API India Private Limited

Manufacturer Address : Plot Nos. A-2, A-2/1, A-2/2, UPSIDC Industrial Area, Bijnor Road, Gajraula-244 235, Distt. Amroha (Uttar Pradesh) India

| Available Reg. Filing : CA, ASMF |

GDUFA

DMF Review : N/A

Rev. Date :

Pay. Date :

DMF Number : 16996

Submission : 2003-12-03

Status : Active

Type : II

Certificate Number : CEP 2021-227 - Rev 02

Issue Date : 2025-03-12

Type : Chemical

Substance Number : 2232

Status : Valid

Registration Number : 230MF10060

Registrant's Address : Plot No. 2G, 2H, 2I, Udyog Vihar, Greater Noida-201 308 (U.P.) India

Initial Date of Registration : 2018-05-08

Latest Date of Registration :

Date of Issue : 2025-06-04

Valid Till : 2028-05-20

Written Confirmation Number : WC-0001

Address of the Firm :

NDC Package Code : 15894-0028

Start Marketing Date : 2015-12-14

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (100kg/100kg)

Marketing Category : BULK INGREDIENT

Registrant Name : Samoh Pharmaceutical Co., Ltd.

Registration Date : 2013-03-07

Registration Number : 20130307-122-G-116-35

Manufacturer Name : Teva API India Pvt. Ltd

Manufacturer Address : Plot No. Q1 ~ Q4, Industrial Area, Ghirogi, Malanpur Distt. Bhind (Madhya Pradesh)-477117 India

GDUFA

DMF Review : Reviewed

Rev. Date : 2014-05-07

Pay. Date : 2012-12-20

DMF Number : 26726

Submission : 2013-01-24

Status : Active

Type : II

Certificate Number : CEP 2010-326 - Rev 06

Issue Date : 2025-03-14

Type : Chemical

Substance Number : 45

Status : Valid

Registration Number : 227MF10141

Registrant's Address : No. 1889, Jingliu Road, Linjiang Industrial Zone, Qiantang New District, Hangzhou, China

Initial Date of Registration : 2015-05-14

Latest Date of Registration :

Date of Issue : 2025-04-24

Valid Till : 2028-05-25

Written Confirmation Number : WC-0002

Address of the Firm :

NDC Package Code : 15894-0038

Start Marketing Date : 2022-01-24

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (1kg/kg)

Marketing Category : BULK INGREDIENT

| Available Reg. Filing : ASMF |

GDUFA

DMF Review : N/A

Rev. Date :

Pay. Date :

DMF Number : 19829

Submission : 2006-10-04

Status : Active

Type : II

Certificate Number : CEP 2017-131 - Rev 06

Issue Date : 2025-03-12

Type : Chemical

Substance Number : 2583

Status : Valid

Registration Number : 305MF10076

Registrant's Address : Plot No. 2G, 2H, 2I, Udyog Vihar, Greater Noida - 201 308 (U.P.) India

Initial Date of Registration : 2023-07-05

Latest Date of Registration :

Date of Issue : 2025-04-24

Valid Till : 2028-05-25

Written Confirmation Number : WC-0002

Address of the Firm :

NDC Package Code : 15894-0004

Start Marketing Date : 2019-08-19

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (100kg/100kg)

Marketing Category : BULK INGREDIENT

Registrant Name : Korea Pharmaceutical Co., Ltd.

Registration Date : 2019-03-06

Registration Number : 20180208-209-J-62(1)

Manufacturer Name : Teva API India Private Limited Gajraula site

Manufacturer Address : Plot No. A-2, A-2/1, A-2/2, UPSIDC Industrial Area, Bijnor Road, Gajraula-244 235, Distt. Amroha (UP) India

| Available Reg. Filing : ASMF |

GDUFA

DMF Review : Reviewed

Rev. Date : 2012-11-23

Pay. Date : 2012-11-13

DMF Number : 22242

Submission : 2008-12-01

Status : Active

Type : II

Certificate Number : CEP 2020-375 - Rev 03

Issue Date : 2025-03-14

Type : Chemical

Substance Number : 2777

Status : Valid

Registration Number : 230MF10103

Registrant's Address : Plot No. 2G, 2H, 2I, Udyog Vihar, Greater Noida-201 308 (U.P.) India

Initial Date of Registration : 2018-08-08

Latest Date of Registration :

Date of Issue : 2025-04-24

Valid Till : 2028-05-25

Written Confirmation Number : WC-0002

Address of the Firm :

NDC Package Code : 15894-0016

Start Marketing Date : 2019-03-26

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (100kg/100kg)

Marketing Category : BULK INGREDIENT

Registrant Name : Samoh Pharmaceutical Co., Ltd.

Registration Date : 2015-12-02

Registration Number : Su2991-23-ND

Manufacturer Name : Teva API India Private Limited

Manufacturer Address : Plot No. A-2, A-2/1, A-2/2, UPSIDC Industrial Area, Gajraula, Distt. JP Nagar (UP) India

| Available Reg. Filing : CA, ASMF |

GDUFA

DMF Review : Reviewed

Rev. Date : 2012-11-30

Pay. Date : 2012-11-13

DMF Number : 14768

Submission : 2000-03-03

Status : Active

Type : II

Certificate Number : CEP 2006-281 - Rev 04

Issue Date : 2025-03-19

Type : Chemical

Substance Number : 596

Status : Valid

Registration Number : 218MF10573

Registrant's Address : Ostravska 305/29, Komarov, 747 70 Opava, Czech Republic

Initial Date of Registration : 2006-06-15

Latest Date of Registration :

NDC Package Code : 84644-003

Start Marketing Date : 2017-12-29

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (100kg/100kg)

Marketing Category : BULK INGREDIENT

| Available Reg. Filing : BR, CA |

GDUFA

DMF Review : Reviewed

Rev. Date : 2012-11-29

Pay. Date : 2012-11-07

DMF Number : 12932

Submission : 1998-04-02

Status : Active

Type : II

Certificate Number : CEP 2002-152 - Rev 07

Issue Date : 2025-03-11

Type : Chemical

Substance Number : 994

Status : Valid

Registration Number : 305MF10110

Registrant's Address : Ostravska 305/29, Komarov, 747 70 Opava, Czech Republic

Initial Date of Registration : 2023-09-20

Latest Date of Registration :

NDC Package Code : 84644-004

Start Marketing Date : 2022-01-26

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (100kg/100kg)

Marketing Category : BULK INGREDIENT

| Available Reg. Filing : ASMF, CA |

GDUFA

DMF Review : Reviewed

Rev. Date : 2017-02-22

Pay. Date : 2017-02-06

DMF Number : 12146

Submission : 1996-10-02

Status : Active

Type : II

Certificate Number : CEP 1997-042 - Rev 13

Issue Date : 2025-12-10

Type : Chemical

Substance Number : 1104

Status : Valid

Date of Issue : 2025-04-24

Valid Till : 2028-05-25

Written Confirmation Number : WC-0002

Address of the Firm :

NDC Package Code : 15894-0039

Start Marketing Date : 2024-04-03

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (1kg/kg)

Marketing Category : BULK INGREDIENT

| Available Reg. Filing : ASMF |

GDUFA

DMF Review : Reviewed

Rev. Date : 2012-12-24

Pay. Date : 2012-11-13

DMF Number : 14729

Submission : 2000-02-25

Status : Active

Type : II

Certificate Number : CEP 2003-073 - Rev 04

Issue Date : 2025-02-28

Type : Chemical

Substance Number : 2059

Status : Valid

Registration Number : 307MF10010

Registrant's Address : 13 Pallagi u(´)t, Debrecen, 4042-Hungary

Initial Date of Registration : 2025-01-09

Latest Date of Registration :

NDC Package Code : 84671-1022

Start Marketing Date : 2020-04-30

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (100kg/100kg)

Marketing Category : BULK INGREDIENT

| Available Reg. Filing : ASMF |

GDUFA

DMF Review : N/A

Rev. Date :

Pay. Date :

DMF Number : 14599

Submission : 1999-11-29

Status : Active

Type : II

Certificate Number : CEP 2019-179 - Rev 02

Issue Date : 2025-10-17

Type : Chemical

Substance Number : 1563

Status : Valid

Registration Number : 307MF10003

Registrant's Address : 13 Pallagi u(´)t, Debrecen, 4042-Hungary

Initial Date of Registration : 2025-01-09

Latest Date of Registration :

NDC Package Code : 84671-1042

Start Marketing Date : 2013-04-17

End Marketing Date : 2026-12-31

Dosage Form (Strength) : POWDER (100kg/100kg)

Marketing Category : BULK INGREDIENT

| Available Reg. Filing : ASMF |

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]

GDUFA

DMF Review : N/A

Rev. Date :

Pay. Date :

DMF Number : 41922

Submission : 2025-06-17

Status : Active

Type : II

GDUFA

DMF Review : Complete

Rev. Date : 2013-08-28

Pay. Date : 2013-08-16

DMF Number : 11742

Submission : 1995-11-14

Status : Active

Type : II

GDUFA

DMF Review : Complete

Rev. Date : 2013-10-24

Pay. Date : 2012-11-13

DMF Number : 26126

Submission : 2012-06-04

Status : Active

Type : II

GDUFA

DMF Review : Complete

Rev. Date : 2015-01-13

Pay. Date : 2014-04-25

DMF Number : 15972

Submission : 2002-05-02

Status : Active

Type : II

GDUFA

DMF Review : N/A

Rev. Date :

Pay. Date :

DMF Number : 27295

Submission : 2013-07-10

Status : Inactive

Type : II

GDUFA

DMF Review : N/A

Rev. Date :

Pay. Date :

DMF Number : 15261

Submission : 2001-01-24

Status : Active

Type : II

GDUFA

DMF Review : Complete

Rev. Date : 2013-07-26

Pay. Date : 2012-11-13

DMF Number : 15985

Submission : 2002-05-28

Status : Active

Type : II

GDUFA

DMF Review : N/A

Rev. Date :

Pay. Date :

DMF Number : 16751

Submission : 2003-08-08

Status : Inactive

Type : II

GDUFA

DMF Review : Complete

Rev. Date : 2012-12-24

Pay. Date : 2012-12-03

DMF Number : 19342

Submission : 2006-04-11

Status : Active

Type : II

GDUFA

DMF Review : Complete

Rev. Date : 2019-01-31

Pay. Date : 2019-01-28

DMF Number : 4871

Submission : 1983-03-14

Status : Active

Type : II

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]TAPI Technology & API Services

Certificate Numbers : CEP 1997-084 - Rev 12

Status : Valid

Issue Date : 2024-05-30

Type : Chemical

Substance Number : 968

TAPI Technology & API Services

Certificate Numbers : CEP 2000-100 - Rev 07

Status : Valid

Issue Date : 2025-01-17

Type : Chemical

Substance Number : 1286

TAPI Technology & API Services

Certificate Numbers : CEP 1998-118 - Rev 08

Status : Valid

Issue Date : 2025-07-11

Type : Chemical

Substance Number : 576

TAPI Technology & API Services

Certificate Numbers : CEP 1999-007 - Rev 08

Status : Valid

Issue Date : 2025-04-01

Type : Chemical

Substance Number : 576

TAPI Technology & API Services

Certificate Numbers : CEP 2014-117 - Rev 03

Status : Valid

Issue Date : 2025-06-30

Type : Chemical

Substance Number : 576

TAPI Technology & API Services

Certificate Numbers : CEP 2001-432 - Rev 06

Status : Valid

Issue Date : 2025-03-11

Type : Chemical

Substance Number : 464

TAPI Technology & API Services

Certificate Numbers : CEP 2014-099 - Rev 02

Status : Valid

Issue Date : 2025-01-23

Type : Chemical

Substance Number : 2406

TAPI Technology & API Services

Certificate Numbers : CEP 2018-267 - Rev 03

Status : Valid

Issue Date : 2025-06-05

Type : Chemical

Substance Number : 2617

TAPI Technology & API Services

Certificate Numbers : CEP 2004-030 - Rev 08

Status : Valid

Issue Date : 2024-03-06

Type : Chemical

Substance Number : 703

TAPI Technology & API Services

Certificate Numbers : R0-CEP 1998-033 - Rev 02

Status : Withdrawn by Holder

Issue Date : 2002-05-02

Type : Chemical

Substance Number : 703

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results] TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 302MF10137

Registrant's Address : Plot No. 2G, 2H, 2I, Udyog Vihar, Greater Noida-201 308 (U.P.) India

Initial Date of Registration : 2020-11-26

Latest Date of Registration : 2020-11-26

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 227MF10251

Registrant's Address : No. 1889, Jingliu Road, Linjiang Industrial Zone, Qiantang New District, Hangzhou, Ch...

Initial Date of Registration : 2015-10-08

Latest Date of Registration : 2015-10-08

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 218MF10573

Registrant's Address : Ostravska 305/29, Komarov, 747 70 Opava, Czech Republic

Initial Date of Registration : 2006-06-15

Latest Date of Registration : 2024-10-31

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 217MF11279

Registrant's Address : Ostravska 305/29, Komarov, 747 70 Opava, Czech Republic

Initial Date of Registration : 2005-12-20

Latest Date of Registration : 2010-07-09

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 305MF10081

Registrant's Address : Plot No. 2G, 2H, 2I, Udyog Vihar, Greater Noida-201 308 (U.P.) India

Initial Date of Registration : 2023-07-12

Latest Date of Registration : 2025-12-11

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 220MF10190

Registrant's Address : Ostravska 305/29, Komarov, 747 70 Opava, Czech Republic

Initial Date of Registration : 2008-08-18

Latest Date of Registration : 2016-03-29

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 305MF10110

Registrant's Address : Ostravska 305/29, Komarov, 747 70 Opava, Czech Republic

Initial Date of Registration : 2023-09-20

Latest Date of Registration : 2023-09-20

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 225MF10001

Registrant's Address : Plot No. 2G, 2H, 2I, Udyog Vihar, Greater Noida-201 308 (U.P.) India

Initial Date of Registration : 2013-01-15

Latest Date of Registration : 2013-01-15

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 306MF10139

Registrant's Address : Plot No. 2G, 2H, 2I, Udyog Vihar, Greater Noida-201 308 (U.P.) India

Initial Date of Registration : 2024-10-31

Latest Date of Registration : 2024-10-31

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI, a leading global supplier of APIs, provides over 350 products and customized CDMO solutions for every stage of development.

TAPI Technology & API Services

Registration Number : 307MF10007

Registrant's Address : Ostravska 305/29, Komarov, 747 70 Opava, Czech Republic

Initial Date of Registration : 2025-01-09

Latest Date of Registration : 2025-01-09

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]Details:

Through the licensing deal for Resmetirom, targeting thyroid hormone receptor beta-1, the agreement aims to advance treatment for Metabolic Dysfunction-Associated Steatohepatitis (MASH).

Lead Product(s): Resmetirom,Denifanstat

Therapeutic Area: Hepatology (Liver, Pancreatic, Gall Bladder) Brand Name: Undisclosed

Study Phase: Phase IIIProduct Type: Miscellaneous

Sponsor: Sagimet Biosciences

Deal Size: Undisclosed Upfront Cash: Undisclosed

Deal Type: Licensing Agreement December 17, 2025

Lead Product(s) : Resmetirom,Denifanstat

Therapeutic Area : Hepatology (Liver, Pancreatic, Gall Bladder)

Highest Development Status : Phase III

Partner/Sponsor/Collaborator : Sagimet Biosciences

Deal Size : Undisclosed

Deal Type : Licensing Agreement

Sagimet Biosciences, TAPI Sign Global License for Resmetirom API in Fixed Dose Program

Details : Through the licensing deal for Resmetirom, targeting thyroid hormone receptor beta-1, the agreement aims to advance treatment for Metabolic Dysfunction-Associated Steatohepatitis (MASH).

Product Name : Undisclosed

Product Type : Miscellaneous

Upfront Cash : Undisclosed

December 17, 2025

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]Services

Analytical

API Manufacturing

API & Drug Product Development

Excipients

Inspections and registrations

Country : Israel

City/Region : Be’er Sheva

Audit Date : 2026-11-24

Audit Type : On-Site

Country : Israel

City/Region : Be’er Sheva

Audit Date : 2023-12-05

Audit Type : On-Site

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]ABOUT THIS PAGE

Teva API is a supplier offers 492 products (APIs, Excipients or Intermediates).

Find a price of Diltiazem Hydrochloride bulk with DMF, CEP, JDMF, WC offered by Teva API

Find a price of Losartan Potassium bulk with DMF, CEP, JDMF, WC offered by Teva API

Find a price of Methyldopa bulk with DMF, CEP, JDMF, WC offered by Teva API

Find a price of Montelukast Sodium bulk with DMF, CEP, JDMF, WC offered by Teva API

Find a price of Pregabalin bulk with DMF, CEP, JDMF, WC offered by Teva API

Find a price of Amitriptyline Hydrochloride bulk with CEP, JDMF, WC offered by Teva API

Find a price of Bromocriptine Mesylate bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Cabergoline bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Carbidopa bulk with DMF, CEP, WC offered by Teva API

Find a price of Clopidogrel bulk with DMF, CEP, WC offered by Teva API

Find a price of Cyclosporine bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Dabigatran Etexilate Mesylate bulk with DMF, CEP, WC offered by Teva API

Find a price of Doxepin Hydrochloride bulk with DMF, CEP, WC offered by Teva API

Find a price of Ergotamine Tartrate bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Ezetimibe bulk with DMF, JDMF, WC offered by Teva API

Find a price of Fluoxetine Hydrochloride bulk with DMF, CEP, WC offered by Teva API

Find a price of Fluvastatin Sodium bulk with DMF, CEP, WC offered by Teva API

Find a price of Imipramine Hydrochloride bulk with DMF, CEP, WC offered by Teva API

Find a price of Irbesartan bulk with DMF, CEP, WC offered by Teva API

Find a price of Montelukast Sodium bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Mupirocin Calcium bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Mycophenolate Mofetil bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Olanzapine bulk with DMF, CEP, WC offered by Teva API

Find a price of Olmesartan Medoxomil bulk with DMF, CEP, WC offered by Teva API

Find a price of Paclitaxel bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Pravastatin bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Quetiapine Hemifumarate bulk with DMF, CEP, WC offered by Teva API

Find a price of Simvastatin bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Solifenacin Succinate bulk with DMF, CEP, WC offered by Teva API

Find a price of Tacrolimus bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Tadalafil bulk with DMF, CEP, WC offered by Teva API

Find a price of Ticagrelor bulk with DMF, CEP, WC offered by Teva API

Find a price of Tobramycin bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Zolpidem Tartrate bulk with DMF, CEP, JDMF offered by Teva API

Find a price of Caspofungin bulk with JDMF, WC offered by Teva API

Find a price of Cyclosporine bulk with DMF, JDMF offered by Teva API

Find a price of Paclitaxel bulk with DMF, JDMF offered by Teva API

Find a price of Pergolide Mesylate bulk with CEP, JDMF offered by Teva API

Find a price of Atenolol bulk with CEP, JDMF offered by Teva API

Find a price of Atorvastatin bulk with CEP, WC offered by Teva API

Find a price of Atracurium Besylate bulk with DMF, CEP offered by Teva API

Find a price of Azithromycin bulk with DMF, CEP offered by Teva API

Find a price of Azithromycin Dihydrate bulk with DMF, CEP offered by Teva API

Find a price of Beclomethasone Dipropionate bulk with DMF, CEP offered by Teva API

Find a price of Betamethasone Dipropionate bulk with DMF, CEP offered by Teva API

Find a price of Betamethasone Valerate bulk with DMF, CEP offered by Teva API

Find a price of Bicalutamide bulk with DMF, CEP offered by Teva API

Find a price of Bleomycin Sulphate bulk with DMF, CEP offered by Teva API

Find a price of Budesonide bulk with DMF, CEP offered by Teva API

Find a price of Buprenorphine bulk with DMF, CEP offered by Teva API

Find a price of Buprenorphine Hydrochloride bulk with DMF, CEP offered by Teva API

Find a price of Calcipotriol bulk with DMF, CEP offered by Teva API

Find a price of Calcitriol bulk with DMF, CEP offered by Teva API

Find a price of Carbidopa bulk with DMF, CEP offered by Teva API

Find a price of Carboplatin bulk with DMF, CEP offered by Teva API

Find a price of Cisatracurium Besylate bulk with DMF, CEP offered by Teva API

Find a price of Clobetasol Propionate bulk with DMF, CEP offered by Teva API

Find a price of Clopidogrel bulk with CEP, WC offered by Teva API

Find a price of Daunorubicin HCl bulk with DMF, CEP offered by Teva API

Find a price of Deferasirox bulk with DMF, CEP offered by Teva API

Find a price of Deferoxamine Mesylate bulk with DMF, CEP offered by Teva API

Find a price of Desmopressin Acetate bulk with DMF, CEP offered by Teva API

Find a price of Dihydroergotamine Mesylate bulk with DMF, CEP offered by Teva API

Find a price of Dorzolamide Hydrochloride bulk with DMF, CEP offered by Teva API

Find a price of Doxorubicin Hydrochloride bulk with DMF, CEP offered by Teva API

Find a price of Drospirenone bulk with DMF, CEP offered by Teva API

Find a price of Edoxaban Tosylate bulk with JDMF, WC offered by Teva API

Find a price of Eletriptan Hydrobromide bulk with DMF, WC offered by Teva API

Find a price of Empagliflozin bulk with DMF, WC offered by Teva API

Find a price of Epirubicin Hydrochloride bulk with DMF, CEP offered by Teva API

Find a price of Ergonovine Maleate bulk with DMF, CEP offered by Teva API

Find a price of Etodolac bulk with DMF, CEP offered by Teva API

Find a price of Etoposide bulk with DMF, CEP offered by Teva API

Find a price of Famciclovir bulk with DMF, WC offered by Teva API

Find a price of Fingolimod Hydrochloride bulk with DMF, CEP offered by Teva API

Find a price of Fludarabine Phosphate bulk with DMF, CEP offered by Teva API

Find a price of Fluticasone Propionate bulk with DMF, CEP offered by Teva API

Find a price of Formoterol Fumarate bulk with DMF, CEP offered by Teva API

Find a price of Gemcitabine bulk with DMF, CEP offered by Teva API

Find a price of Hydrochlorothiazide bulk with DMF, CEP offered by Teva API

Find a price of Imatinib Mesylate bulk with DMF, CEP offered by Teva API

Find a price of Irbesartan bulk with DMF, CEP offered by Teva API

Find a price of Lamotrigine bulk with DMF, CEP offered by Teva API

Find a price of Letrozole bulk with DMF, CEP offered by Teva API

Find a price of Loperamide Hydrochloride bulk with DMF, CEP offered by Teva API

Find a price of Losartan Potassium bulk with DMF, CEP offered by Teva API

Find a price of Lovastatin bulk with DMF, CEP offered by Teva API

Find a price of Medroxyprogesterone Acetate bulk with DMF, CEP offered by Teva API

Find a price of Megestrol Acetate bulk with DMF, CEP offered by Teva API

Find a price of Methylergonovine bulk with CEP, JDMF offered by Teva API

Find a price of Metoprolol Succinate bulk with DMF, CEP offered by Teva API

Find a price of Mitomycin bulk with DMF, CEP offered by Teva API

Find a price of Modafinil bulk with DMF, CEP offered by Teva API

Find a price of Mometasone Furoate bulk with DMF, CEP offered by Teva API

Find a price of Mupirocin bulk with DMF, CEP offered by Teva API

Find a price of Nicergoline bulk with CEP, JDMF offered by Teva API

Find a price of Nifedipine bulk with DMF, CEP offered by Teva API

Find a price of Olanzapine bulk with DMF, CEP offered by Teva API

Find a price of Omeprazole bulk with DMF, CEP offered by Teva API

Find a price of Ondansetron Hydrochloride bulk with DMF, JDMF offered by Teva API

Find a price of Oxaliplatin bulk with DMF, CEP offered by Teva API

Find a price of Pioglitazone Hydrochloride bulk with DMF, WC offered by Teva API

Find a price of Pregabalin bulk with DMF, CEP offered by Teva API

Find a price of Probenecid bulk with DMF, CEP offered by Teva API

Find a price of Risperidone bulk with DMF, CEP offered by Teva API

Find a price of Rivaroxaban bulk with DMF, CEP offered by Teva API

Find a price of Rocuronium Bromide bulk with DMF, CEP offered by Teva API

Find a price of Sofosbuvir bulk with DMF, WC offered by Teva API

Find a price of Terazosin HCl bulk with DMF, CEP offered by Teva API

Find a price of Timolol Maleate bulk with DMF, CEP offered by Teva API

Find a price of Triamcinolone Acetonide bulk with DMF, CEP offered by Teva API

Find a price of Venlafaxine Hydrochloride bulk with DMF, CEP offered by Teva API

Find a price of Zoledronic Acid bulk with DMF, CEP offered by Teva API

Find a price of Azithromycin bulk with DMF offered by Teva API

Find a price of Beclomethasone Dipropionate bulk with CEP offered by Teva API

Find a price of Carbamazepine bulk with DMF offered by Teva API

Find a price of Desvenlafaxine Succinate bulk with WC offered by Teva API

Find a price of Fulvestrant bulk with CEP offered by Teva API

Find a price of Mupirocin Calcium bulk with JDMF offered by Teva API

Find a price of Ondansetron Hydrochloride bulk with JDMF offered by Teva API

Find a price of Rosuvastatin Calcium bulk with DMF offered by Teva API

Find a price of Torsemide bulk with CEP offered by Teva API

Find a price of Trazodone Hydrochloride bulk with WC offered by Teva API

Find a price of Venlafaxine Hydrochloride bulk with CEP offered by Teva API

Find a price of Acyclovir bulk with CEP offered by Teva API

Find a price of Alfacalcidol bulk with CEP offered by Teva API

Find a price of Allopurinol bulk with CEP offered by Teva API

Find a price of Anastrozole bulk with CEP offered by Teva API

Find a price of Apixaban bulk with DMF offered by Teva API

Find a price of Aripiprazole bulk with CEP offered by Teva API

Find a price of Atorvastatin bulk with CEP offered by Teva API

Find a price of Azacitidine bulk with DMF offered by Teva API

Find a price of Aztreonam bulk with DMF offered by Teva API

Find a price of Belumosudil bulk with DMF offered by Teva API

Find a price of Betamethasone bulk with CEP offered by Teva API

Find a price of Betamethasone Acetate bulk with DMF offered by Teva API

Find a price of Bivalirudin bulk with DMF offered by Teva API

Find a price of Bortezomib bulk with DMF offered by Teva API

Find a price of Brexpiprazole bulk with DMF offered by Teva API

Find a price of Budesonide bulk with CEP offered by Teva API

Find a price of Butorphanol Tartrate bulk with DMF offered by Teva API

Find a price of Cabazitaxel bulk with DMF offered by Teva API

Find a price of Calcipotriol bulk with CEP offered by Teva API

Find a price of Capecitabine bulk with DMF offered by Teva API

Find a price of Carfilzomib bulk with DMF offered by Teva API

Find a price of Carvedilol bulk with DMF offered by Teva API

Find a price of Carvedilol Phosphate bulk with DMF offered by Teva API

Find a price of Caspofungin bulk with DMF offered by Teva API

Find a price of Cefadroxil bulk offered by Teva API

Find a price of Choline Fenofibrate bulk with DMF offered by Teva API

Find a price of Cilostazol bulk with DMF offered by Teva API

Find a price of Cinacalcet Hydrochloride bulk with DMF offered by Teva API

Find a price of Cisplatin bulk with CEP offered by Teva API

Find a price of Clarithromycin bulk with DMF offered by Teva API

Find a price of Clomiphene Citrate bulk with DMF offered by Teva API

Find a price of Crisaborole bulk with DMF offered by Teva API

Find a price of Cyclosporine bulk with DMF offered by Teva API

Find a price of Cyproterone Acetate bulk with CEP offered by Teva API

Find a price of Darifenacin Hydrobromide bulk with DMF offered by Teva API

Find a price of Dasatinib bulk with DMF offered by Teva API

Find a price of Desfesoterodine bulk with DMF offered by Teva API

Find a price of Desonide bulk with DMF offered by Teva API

Find a price of Desvenlafaxine Fumarate bulk with DMF offered by Teva API

Find a price of Desvenlafaxine Succinate bulk with DMF offered by Teva API

Find a price of Deutetrabenazine bulk with DMF offered by Teva API

Find a price of Dexrazoxane bulk with DMF offered by Teva API

Find a price of Diflorasone bulk with DMF offered by Teva API

Find a price of Difluprednate bulk with DMF offered by Teva API

Find a price of Dimethyl Fumarate bulk with DMF offered by Teva API

Find a price of Diroximel fumarate bulk with DMF offered by Teva API

Find a price of Docetaxel bulk with DMF offered by Teva API

Find a price of Docosanol bulk with WC offered by Teva API

Find a price of Donepezil bulk with DMF offered by Teva API

Find a price of Doxcercalciferol bulk with DMF offered by Teva API

Find a price of Duloxetine Hydrochloride bulk with DMF offered by Teva API

Find a price of Eptifibatide bulk with DMF offered by Teva API

Find a price of Ergotamine Tartrate bulk with JDMF offered by Teva API

Find a price of Erlotinib Hydrochloride bulk with DMF offered by Teva API

Find a price of Eszopiclone bulk with DMF offered by Teva API

Find a price of Exenatide bulk with DMF offered by Teva API

Find a price of Ezetimibe bulk with DMF offered by Teva API

Find a price of Febuxostat bulk with DMF offered by Teva API

Find a price of Ferric Citrate bulk with WC offered by Teva API

Find a price of Finerenone bulk with DMF offered by Teva API

Find a price of Fludrocortisone Acetate bulk with DMF offered by Teva API

Find a price of Flunisolide bulk with DMF offered by Teva API

Find a price of Fluocinolone Acetonide bulk with DMF offered by Teva API

Find a price of Fluocinonide bulk with DMF offered by Teva API

Find a price of Fluorometholone Acetate bulk with DMF offered by Teva API

Find a price of Fluorouracil bulk with CEP offered by Teva API

Find a price of Fluticasone Furoate bulk with CEP offered by Teva API

Find a price of Fluvoxamine bulk with DMF offered by Teva API

Find a price of Fulvestrant bulk with DMF offered by Teva API

Find a price of Furosemide bulk with DMF offered by Teva API

Find a price of Gabapentin bulk with DMF offered by Teva API

Find a price of Galantamine Hydrobromide bulk with DMF offered by Teva API

Find a price of Gemfibrozil bulk with DMF offered by Teva API

Find a price of Haloperidol bulk with DMF offered by Teva API

Find a price of Haloperidol Decanoate bulk with DMF offered by Teva API

Find a price of Ibrutinib bulk with DMF offered by Teva API

Find a price of Icatibant Acetate bulk with DMF offered by Teva API

Find a price of Idarubicin Hydrochloride bulk with DMF offered by Teva API

Find a price of Imatinib Mesylate bulk with DMF offered by Teva API

Find a price of Imiquimod bulk with DMF offered by Teva API

Find a price of Irbesartan bulk with CEP offered by Teva API

Find a price of Iron Sucrose bulk with WC offered by Teva API

Find a price of Labetalol Hydrochloride bulk with DMF offered by Teva API

Find a price of Lacosamide bulk with DMF offered by Teva API

Find a price of Lansoprazole bulk with DMF offered by Teva API

Find a price of Latanoprost bulk with DMF offered by Teva API

Find a price of Leuprolide Acetate bulk offered by Teva API

Find a price of Levalbuterol Hydrochloride bulk with DMF offered by Teva API

Find a price of Levetiracetam bulk offered by Teva API

Find a price of Levodopa bulk with DMF offered by Teva API

Find a price of Levofloxacin bulk with DMF offered by Teva API

Find a price of Linaclotide bulk with DMF offered by Teva API

Find a price of Linagliptin bulk with DMF offered by Teva API

Find a price of Linezolid bulk with DMF offered by Teva API

Find a price of Losartan Potassium bulk with CEP offered by Teva API

Find a price of Lurasidone Hydrochloride bulk with DMF offered by Teva API

Find a price of Macitentan bulk with DMF offered by Teva API

Find a price of Medroxyprogesterone Acetate bulk with CEP offered by Teva API

Find a price of Memantine Hydrochloride bulk with DMF offered by Teva API

Find a price of Metformin bulk offered by Teva API

Find a price of Methyldopa bulk with CEP offered by Teva API

Find a price of Methylergonovine bulk with JDMF offered by Teva API

Find a price of Methylergonovine Maleate bulk with DMF offered by Teva API

Find a price of Metoprolol Tartrate bulk with DMF offered by Teva API

Find a price of Micafungin bulk with DMF offered by Teva API

Find a price of Migalastat bulk with WC offered by Teva API

Find a price of Milk Thistle Extract bulk with CEP offered by Teva API

Find a price of Mirtazapine bulk with DMF offered by Teva API

Find a price of Modafinil bulk with CEP offered by Teva API

Find a price of Mometasone Furoate bulk with CEP offered by Teva API

Find a price of Mycophenolate Sodium bulk with DMF offered by Teva API

Find a price of Nabumetone bulk with CEP offered by Teva API

Find a price of Naproxen bulk with DMF offered by Teva API

Find a price of Nateglinide bulk with DMF offered by Teva API

Find a price of Nefazodone Hydrochloride bulk with DMF offered by Teva API

Find a price of Nicergoline bulk with JDMF offered by Teva API

Find a price of Nilotinib bulk with DMF offered by Teva API

Find a price of Nomegestrol Acetate bulk with CEP offered by Teva API

Find a price of Norgestimate bulk with DMF offered by Teva API

Find a price of Octreotide Acetate bulk with DMF offered by Teva API

Find a price of Olmesartan Medoxomil bulk with CEP offered by Teva API

Find a price of Omeprazole bulk with CEP offered by Teva API

Find a price of Ondansetron bulk with DMF offered by Teva API

Find a price of Paclitaxel bulk with DMF offered by Teva API

Find a price of Pacritinib bulk with DMF offered by Teva API

Find a price of Palbociclib bulk with DMF offered by Teva API

Find a price of Paliperidone bulk with DMF offered by Teva API

Find a price of Paliperidone Palmitate bulk with DMF offered by Teva API

Find a price of Palonosetron bulk with DMF offered by Teva API

Find a price of Pancuronium Bromide bulk with DMF offered by Teva API

Find a price of Pantoprazole Sodium bulk with DMF offered by Teva API

Find a price of Paricalcitol bulk with DMF offered by Teva API

Find a price of Pemetrexed bulk with DMF offered by Teva API

Find a price of Pemetrexed Disodium bulk with JDMF offered by Teva API

Find a price of Pentoxifylline bulk with DMF offered by Teva API

Find a price of Perampanel bulk with DMF offered by Teva API

Find a price of Potassium Citrate bulk with DMF offered by Teva API

Find a price of Pralatrexate bulk with DMF offered by Teva API

Find a price of Prasugrel Hydrochloride bulk with DMF offered by Teva API

Find a price of Pravastatin bulk with JDMF offered by Teva API

Find a price of Prednicarbate bulk with DMF offered by Teva API

Find a price of Quetiapine Hemifumarate bulk with CEP offered by Teva API

Find a price of Raloxifene Hydrochloride bulk with DMF offered by Teva API

Find a price of Ramelteon bulk with DMF offered by Teva API

Find a price of Risedronate Sodium bulk with DMF offered by Teva API

Find a price of Romidepsin bulk with DMF offered by Teva API

Find a price of Rosiglitazone Maleate bulk with DMF offered by Teva API

Find a price of Rotigotine bulk with DMF offered by Teva API

Find a price of Sacubitril-Valsartan bulk with DMF offered by Teva API

Find a price of Salbutamol Sulphate bulk with CEP offered by Teva API

Find a price of Saxagliptin bulk with DMF offered by Teva API

Find a price of Semaglutide bulk with DMF offered by Teva API

Find a price of Sildenafil Citrate bulk with DMF offered by Teva API

Find a price of Silver Sulfadiazine bulk with DMF offered by Teva API

Find a price of Simvastatin bulk with CEP offered by Teva API

Find a price of Sitagliptin Malate bulk with WC offered by Teva API

Find a price of Sitagliptin Phosphate bulk with DMF offered by Teva API

Find a price of Sofosbuvir bulk with DMF offered by Teva API

Find a price of Solifenacin Succinate bulk with CEP offered by Teva API

Find a price of Sorafenib bulk with DMF offered by Teva API

Find a price of Sotorasib bulk with DMF offered by Teva API

Find a price of Sugammadex Sodium bulk with DMF offered by Teva API

Find a price of Sunitinib bulk with DMF offered by Teva API

Find a price of Tacrolimus bulk with JDMF offered by Teva API

Find a price of Tamoxifen Citrate bulk with DMF offered by Teva API

Find a price of Tapinarof bulk with DMF offered by Teva API

Find a price of Terazosin HCl bulk with DMF offered by Teva API

Find a price of Terguride hydrogen maleate bulk with DMF offered by Teva API

Find a price of Ticlopidine bulk with DMF offered by Teva API

Find a price of Tigecycline bulk with DMF offered by Teva API

Find a price of Tiotropium Bromide bulk with DMF offered by Teva API

Find a price of Tirzepatide bulk with DMF offered by Teva API

Find a price of Tobramycin bulk with JDMF offered by Teva API

Find a price of Tolterodine Tartrate bulk with DMF offered by Teva API

Find a price of Torsemide bulk with DMF offered by Teva API

Find a price of Trazodone Hydrochloride bulk with DMF offered by Teva API

Find a price of Trimethoprim bulk with DMF offered by Teva API

Find a price of Trimipramine bulk offered by Teva API

Find a price of Ulipristal Acetate bulk with DMF offered by Teva API

Find a price of Umeclidinium Bromide bulk with DMF offered by Teva API

Find a price of Valacyclovir Hydrochloride bulk with DMF offered by Teva API

Find a price of Valrubicin bulk with DMF offered by Teva API

Find a price of Vecuronium Bromide bulk with DMF offered by Teva API

Find a price of Verapamil Hydrochloride bulk with DMF offered by Teva API

Find a price of Vilazodone Hydrochloride bulk with DMF offered by Teva API

Find a price of Warfarin Sodium bulk with DMF offered by Teva API

Find a price of Zaleplon bulk with DMF offered by Teva API

Find a price of Zoledronate Disodium bulk with DMF offered by Teva API

Find a price of Zolmitriptan bulk with DMF offered by Teva API

Find a price of Tigecycline, Form II bulk with CEP offered by Teva API

Find a price of Cyclosporine 3 bulk with JDMF offered by Teva API

Find a price of Alendronate Sodium bulk offered by Teva API

Find a price of Atenolol bulk offered by Teva API

Find a price of Azithromycin bulk offered by Teva API

Find a price of Aztreonam bulk offered by Teva API

Find a price of Beclomethasone Dipropionate bulk offered by Teva API

Find a price of Candesartan Cilexetil bulk offered by Teva API

Find a price of Carbamazepine bulk offered by Teva API

Find a price of Cefaclor bulk offered by Teva API

Find a price of Cefazolin Sodium bulk offered by Teva API

Find a price of Cefdinir bulk offered by Teva API

Find a price of Cefprozil bulk offered by Teva API

Find a price of Cephalexin bulk offered by Teva API

Find a price of Cephalexin Monohydrate bulk offered by Teva API

Find a price of Cephalosporin bulk offered by Teva API

Find a price of Cephradine bulk offered by Teva API

Find a price of Chlorthalidone bulk offered by Teva API

Find a price of Clobetasol Propionate bulk offered by Teva API

Find a price of Cloxacillin Sodium bulk offered by Teva API

Find a price of Conjugated Estrogens bulk offered by Teva API

Find a price of Cyclacillin bulk offered by Teva API

Find a price of Desloratadine bulk offered by Teva API

Find a price of Dihydroergocristine bulk offered by Teva API

Find a price of Dihydroergotoxine Mesylate bulk offered by Teva API

Find a price of Disodium Pamidronate Pentahydrate bulk offered by Teva API

Find a price of Etoposide bulk offered by Teva API

Find a price of Fexofenadine Hydrochloride bulk offered by Teva API

Find a price of Fosamprenavir bulk offered by Teva API

Find a price of Gatifloxacin bulk offered by Teva API

Find a price of Glatiramer Acetate bulk offered by Teva API

Find a price of Halobetasol bulk offered by Teva API

Find a price of Hydrocortisone Butyrate bulk offered by Teva API

Find a price of Ibandronate Sodium bulk offered by Teva API

Find a price of Irbesartan bulk offered by Teva API

Find a price of Labetalol Hydrochloride bulk offered by Teva API

Find a price of Lisinopril bulk offered by Teva API

Find a price of Lisuride bulk offered by Teva API

Find a price of Lisuride Maleate bulk offered by Teva API

Find a price of Lorazepam bulk offered by Teva API

Find a price of Lr-103 bulk offered by Teva API

Find a price of Lubiprostone bulk offered by Teva API

Find a price of Mesalazine bulk offered by Teva API

Find a price of Misoprostol bulk offered by Teva API

Find a price of Mitoxantrone bulk offered by Teva API

Find a price of Naproxen bulk offered by Teva API

Find a price of Oxacillin Sodium bulk offered by Teva API

Find a price of Oxazepam bulk offered by Teva API

Find a price of Pantoprazole Sodium bulk offered by Teva API

Find a price of Paroxetine Hydrochloride bulk offered by Teva API

Find a price of Penicillin G Sulfoxide bulk offered by Teva API

Find a price of Penicillin V Potassium bulk offered by Teva API

Find a price of Raloxifene Hydrochloride bulk offered by Teva API

Find a price of Rasagiline Mesylate bulk offered by Teva API

Find a price of Rosuvastatin Calcium bulk offered by Teva API

Find a price of Selegiline Hydrochloride bulk offered by Teva API

Find a price of Sertraline Hydrochloride bulk offered by Teva API

Find a price of Simvastatin bulk offered by Teva API

Find a price of Sodium Dicloxacillin bulk offered by Teva API

Find a price of Sulfamethoxazole bulk offered by Teva API

Find a price of Telmisartan bulk offered by Teva API

Find a price of Terazosin HCl bulk offered by Teva API

Find a price of Terbinafine Hydrochloride bulk offered by Teva API

Find a price of Terfenadine bulk offered by Teva API

Find a price of Teriparatide Acetate bulk offered by Teva API

Find a price of Thiotepa bulk offered by Teva API

Find a price of Triamcinolone Acetonide bulk offered by Teva API

Find a price of Zolpidem Tartrate bulk offered by Teva API

Find a price of Zonisamide bulk offered by Teva API

Find a price of MANUFACTURING SITE, FACILITIES, PERSONNEL AND OPERATING PROCEDURES IN BEER SHEVA, ISREAL. bulk offered by Teva API

Find a price of DIHYDRO DANE SALT bulk offered by Teva API

Find a price of PARAHYDROXY DANE SALT bulk offered by Teva API

Find a price of Abaloparatide bulk offered by Teva API

Find a price of Abemaciclib bulk offered by Teva API

Find a price of Abiraterone Acetate bulk offered by Teva API

Find a price of Abrocitinib bulk offered by Teva API

Find a price of Acetic Acid bulk offered by Teva API

Find a price of Adagrasib bulk offered by Teva API

Find a price of Afatinib bulk offered by Teva API

Find a price of Alclometasone Dipropionate bulk offered by Teva API

Find a price of Alpelisib bulk offered by Teva API

Find a price of Amcinonide bulk offered by Teva API

Find a price of Apalutamide bulk offered by Teva API

Find a price of Asciminib bulk offered by Teva API

Find a price of Atomoxetin Hydrochloride bulk offered by Teva API

Find a price of Atosiban bulk offered by Teva API

Find a price of Avacopan bulk offered by Teva API

Find a price of Avapritinib bulk offered by Teva API

Find a price of Baloxavir Marboxil bulk offered by Teva API

Find a price of Baricitinib bulk offered by Teva API

Find a price of Belzutifan bulk offered by Teva API

Find a price of Bempedoic Acid bulk offered by Teva API

Find a price of Brexanolone bulk offered by Teva API

Find a price of Cantharidin bulk offered by Teva API

Find a price of Capivasertib bulk offered by Teva API

Find a price of Capmatinib bulk offered by Teva API

Find a price of CAS 137281-39-1 bulk offered by Teva API

Find a price of Clascoterone bulk offered by Teva API

Find a price of Dabigatran Etexilate Mesylate bulk offered by Teva API

Find a price of Dabrafenib Mesylate bulk offered by Teva API

Find a price of Daprodustat bulk offered by Teva API

Find a price of Darolutamide bulk offered by Teva API

Find a price of Dexamethasone bulk offered by Teva API

Find a price of Diazoxide bulk offered by Teva API

Find a price of Elacestrant bulk offered by Teva API

Find a price of Elagolix Sodium bulk offered by Teva API

Find a price of Eltrombopag bulk offered by Teva API

Find a price of Entrectinib bulk offered by Teva API

Find a price of Enzalutamide bulk offered by Teva API

Find a price of Erdafitinib bulk offered by Teva API

Find a price of Ergometrine bulk offered by Teva API

Find a price of Etrasimod bulk offered by Teva API

Find a price of Fedratinib bulk offered by Teva API

Find a price of Ferric Carboxymaltose bulk offered by Teva API

Find a price of Fidaxomicin bulk offered by Teva API

Find a price of Filgrastim bulk offered by Teva API

Find a price of Fluorometholone bulk offered by Teva API

Find a price of Glasdegib bulk offered by Teva API

Find a price of Glycerol Phenylbutyrate bulk offered by Teva API

Find a price of Ivosidenib bulk offered by Teva API

Find a price of Ixazomib Citrate bulk offered by Teva API

Find a price of Larotrectinib bulk offered by Teva API

Find a price of Lemborexant bulk offered by Teva API

Find a price of Lenalidomide bulk offered by Teva API

Find a price of Letermovir bulk offered by Teva API

Find a price of Lorlatinib bulk offered by Teva API

Find a price of Lotilaner bulk offered by Teva API

Find a price of Lovastatin bulk offered by Teva API

Find a price of Lumateperone Tosylate bulk offered by Teva API

Find a price of Mavacamten bulk offered by Teva API

Find a price of Maxacalcitol bulk offered by Teva API

Find a price of Metopimazine bulk offered by Teva API

Find a price of Midostaurin bulk offered by Teva API

Find a price of Momelotinib bulk offered by Teva API

Find a price of Neratinib bulk offered by Teva API

Find a price of Nintedanib Esylate bulk offered by Teva API

Find a price of Niraparib Tosylate bulk offered by Teva API

Find a price of Nirogacestat Hydrobromide bulk offered by Teva API

Find a price of Nitrofurantoin bulk offered by Teva API

Find a price of Nusinersen bulk offered by Teva API

Find a price of Olodaterol Hydrochloride bulk offered by Teva API

Find a price of Osimertinib Mesylate bulk offered by Teva API

Find a price of Pirtobrutinib bulk offered by Teva API

Find a price of Ponesimod bulk offered by Teva API

Find a price of Prasterone bulk offered by Teva API

Find a price of Prasugrel Hydrobromide bulk offered by Teva API

Find a price of Prednisolone bulk offered by Teva API

Find a price of Relugolix bulk offered by Teva API

Find a price of Ribociclib bulk offered by Teva API

Find a price of Rilpivirine Hydrochloride bulk offered by Teva API

Find a price of Rimegepant Sulfate bulk offered by Teva API

Find a price of Ripretinib bulk offered by Teva API

Find a price of Risdiplam bulk offered by Teva API

Find a price of Ritlecitinib bulk offered by Teva API

Find a price of Roxadustat bulk offered by Teva API

Find a price of Rusfertide bulk offered by Teva API

Find a price of Samidorphan bulk offered by Teva API

Find a price of Silymarin bulk offered by Teva API

Find a price of Sotagliflozin bulk offered by Teva API

Find a price of Sparsentan bulk offered by Teva API

Find a price of Tafamidis bulk offered by Teva API

Find a price of Tafamidis Meglumine bulk offered by Teva API

Find a price of Telotristat Etiprate bulk offered by Teva API

Find a price of Ticagrelor bulk offered by Teva API

Find a price of Tivozanib bulk offered by Teva API

Find a price of Triamcinolone bulk offered by Teva API

Find a price of Triheptanoin bulk offered by Teva API

Find a price of Trilaciclib bulk offered by Teva API

Find a price of Tucatinib bulk offered by Teva API

Find a price of Upadacitinib bulk offered by Teva API

Find a price of Valbenazine Tosylate bulk offered by Teva API

Find a price of Vamorolone bulk offered by Teva API

Find a price of Varenicline Tartrate bulk offered by Teva API

Find a price of Venetoclax bulk offered by Teva API

Find a price of Vericiguat bulk offered by Teva API

Find a price of Vilanterol Trifenatate bulk offered by Teva API

Find a price of Voclosporin bulk offered by Teva API

Find a price of Zavegepant HCl bulk offered by Teva API

Find a price of Zuranolone bulk offered by Teva API

Teva API

Teva API