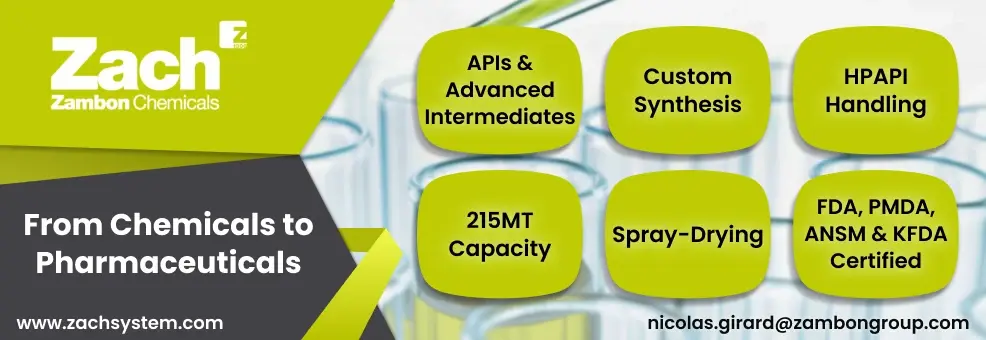

Zach System is committed to providing Highly Customized Solutions for all your Development Programs.

Zach System is committed to providing Highly Customized Solutions for all your Development Programs.

01 17Extraction & Isolation

02 2Ultrafiltration / Nanofiltration

01 1ZACH System SA

02 1EUROAPI

03 2Axplora

04 1Acharya Chemicals

05 1Avara Pharmaceutical Services

06 1Bio-Technology General Israel Ltd.

07 2Bioindustria L.I.M. Spa

08 1Cook Pharmica LLC.

09 1DOTTIKON EXCLUSIVE SYNTHESIS AG

10 2Dalton Pharma Services

11 1GBI

12 1Grace

13 1Procos

14 1SAS Yslab

15 2ScinoPharm Taiwan Ltd

01 2Canada

02 3France

03 2Germany

04 1India

05 1Israel

06 3Italy

07 1Switzerland

08 2Taiwan

09 4U.S.A

Pharma Service : API Manufacturing

ULTRAFILTRATION & NANOFILTRATION

Category : Separation & Purification

Sub Category : Ultrafiltration / Nanofiltration

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

THERAPEUTIC PROTEIN EXTRACTION

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

BIOMOLECULE & NATURAL EXTRACT PURIFICATI...

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

MACROMOLECULAR SEPARATION & PURIFICATION

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

SELECTION AND CONTROL OF EXTRACTION PROC...

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

CHROMATOGRAPHY & COLUMNS FROM 10 TO 80 C...

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

EXTRACTION & ISOLATION TECHNOLOGY

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

Category : Separation & Purification

Sub Category : Extraction & Isolation

Pharma Service : API Manufacturing