Interview #SpeakPharma

“Over 500 million syringes of our hyaluronic acid have been safely used worldwide”

This week, SpeakPharma interviews Marie-Armelle Floc’h, Chief of Quality and Regulatory Affairs at HTL Biotechnology, a g...

“We’re expanding our CDMO capabilities to meet the next wave of complex therapies, starting with oncology.”

This week, SpeakPharma interviews Dr. Abdelaziz Toumi, Chief Executive Officer of Lupin Manufacturing Solutions (LMS). With o...

“We are building capabilities to stay ahead of the curve, and align with future needs of global healthcare”

This week, SpeakPharma interviews Girish Chovatia, Chairman and Managing Director of Ami Lifesciences. Since its inception in 2...

“We bridge the gap between chemistry and performance to deliver precise, optimized micronization for complex APIs.”

This week, SpeakPharma interviews Stefano Martinoli, Chief Executive Officer of Munit SA, a Swiss company that specializes...

"50 Years of Innovation: Mikart's legacy and what's next in CDMO excellence"

This week, SpeakPharma interviews Michael

Kallelis, CEO of Mikart, a leading contract development and manufacturing organizati...

Alchem NicSelect™ grants customers royalty-free access to T-MAX™ tech for 3-in-1 vape satisfaction in flavour-restricted markets

With increasing flavour bans in key markets,

vaping brands are facing significant challenges in providing satisfying

alternat...

“Our unmatched efficiency and track record of faster DMF filings give our customers a critical competitive advantage”

This week, SpeakPharma interviews Pete Werth III, the new president of ChemWerth, a company that has been at the forefront of t...

“Translational Pharmaceutics, our flagship platform for drug development, empowers our clients with unparalleled flexibility”

This week, SpeakPharma interviews Denise Sutton, Chief

Operating Officer and Site Head at Quotient Sciences’ Nottingham ...

“LGM Pharma has made significant strides in meeting the evolving needs of its clients”

This week, SpeakPharma interviews four senior executives of LGM Pharma — Shailesh Vengurlekar (Senior VP, Quality an...

“Due to its 20-year mastery in micronization, Inke has emerged a cornerstone in treating global respiratory diseases”

This week, SpeakPharma interviews Miquel Bachs, CEO of Inke, a company with over two decades of expertise in micronization and ...

“We have built considerable expertise in GLP-1 drug development through our oral peptide programs”

This week, Speak Pharma interviews Dr. Andrew Lewis,

Chief Scientific Officer at Quotient Sciences, a drug development and man...

"ICE is pioneering sustainability, innovation in bile acid research for neurodegenerative diseases"

This week, SpeakPharma interviews Roger Viney, Chief Commercial Officer of ICE Pharma, a world-leading manufacturer of spe...

“We’re unlocking life-changing potential in complex molecules, without sacrificing time to market”

This week, SpeakPharma interviews Mike Riley, CEO of Veranova, a leading contract development and manufacturing organization (C...

“Topscience’s expertise in producing pharma-grade sodium hyaluronate has made it a leader in China”

This week, SpeakPharma interviews Fu

Qiang, Deputy General Manager of Shandong Topscience Biotech, one of China’s leadin...

"Axplora’s leading position in ADCs and how it is well-placed to serve the burgeoning GLP1 market"

This week, SpeakPharma interviews Martin Meeson, CEO of

Axplora, a leading and

reliable API manufacturing partner to some of ...

“Through innovation, we’ve emerged as world leaders in biopolymers”

This week, SpeakPharma interviews Anne-Laure Gaudry, Head of Innovation and R&D at HTL Biotechnology, a global producer and dev...

“Athena’s R&D prowess is its key differentiator, with our India unit bringing in excellent knowledge”

This week, SpeakPharma interviews Alexandre Williams, owner and director of Athena Pharmaceutiques, which is a trusted par...

“LGM operates as a trusted partner by seeking out optimal source of APIs for clients”

This

week, SpeakPharma interviews Selwyn

Lustman, Senior Vice President, Global Sourcing and Procurement, LGM Pharma, a tailo...

“Our Translational Pharmaceutics platform shortens drug development timelines by over 12 months”

This week, SpeakPharma interviews John McDermott, Vice

President of Scientific Consulting at Quotient Sciences, a drug develop...

“We are working towards providing affordable, high-quality APIs”

This week, SpeakPharma

interviews Dr. N.V. Rao, Chairman and Managing Director of Hyderabad (India)-based Metrochem API, one o...

“We want to emerge as the most trusted API firm in complex drug molecule segments”

This week, Speakpharma interviews Dr. Jagadeesh Babu Rangisetty, CEO of Biophore India Pharmaceuticals. The Hyderabad (India)-b...

“We owe our success to our focus on R&D, quality and better service”

This week, SpeakPharma interviews Ella Qu, General Manager & Director at China-headquartered Boai NKY Pharmaceuticals Limit...

“Polpharma has invested over €35 million in a new facility to handle HPAPIs”

Over the recent years, the market for contract development and manufacturing organizations (CDMOs) has been growing at a fast c...

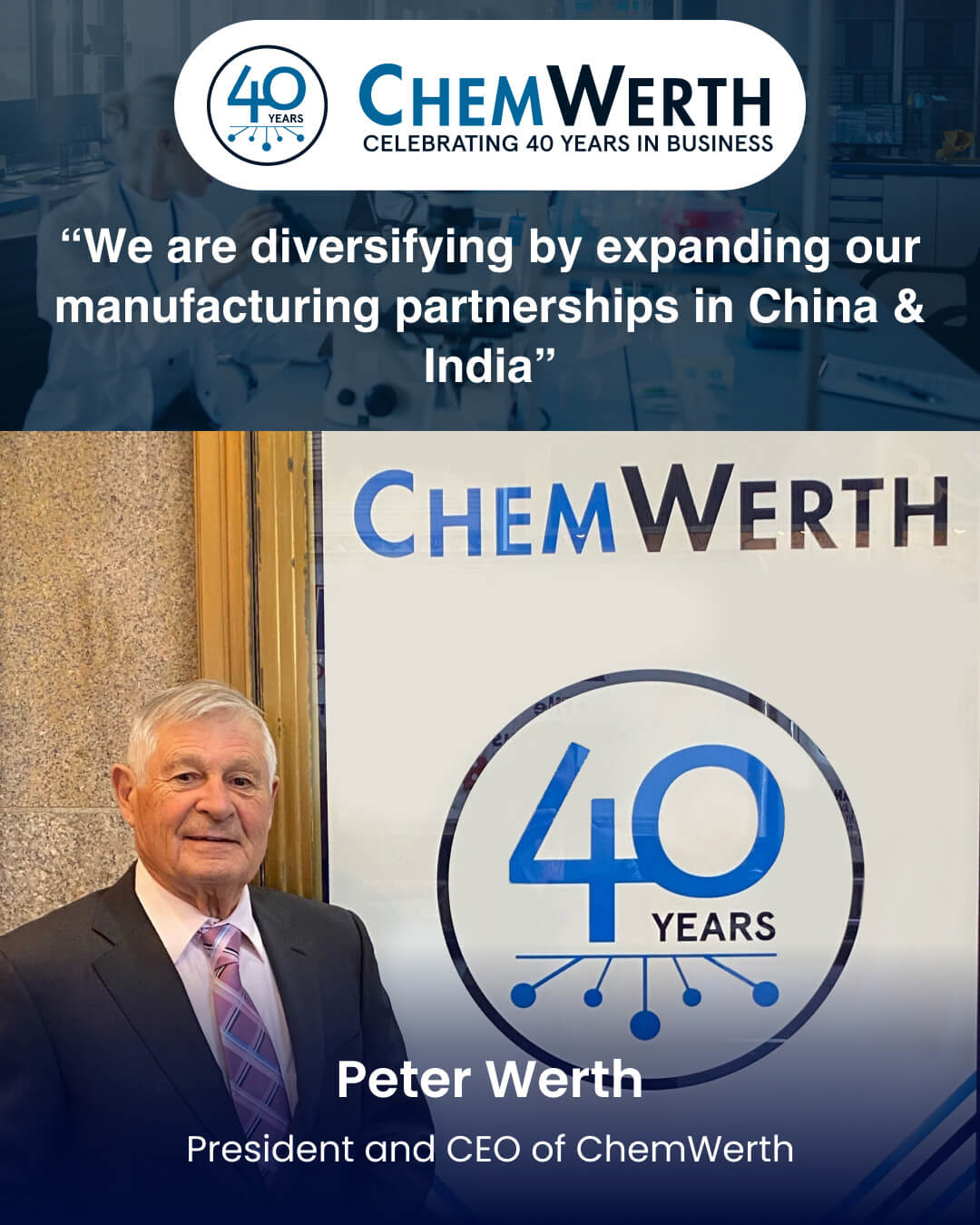

“We are diversifying by expanding our manufacturing partnerships in China & India”

This

week, SpeakPharma interviews Peter Werth, President and CEO of ChemWerth, a full-service generic drug development and sup...

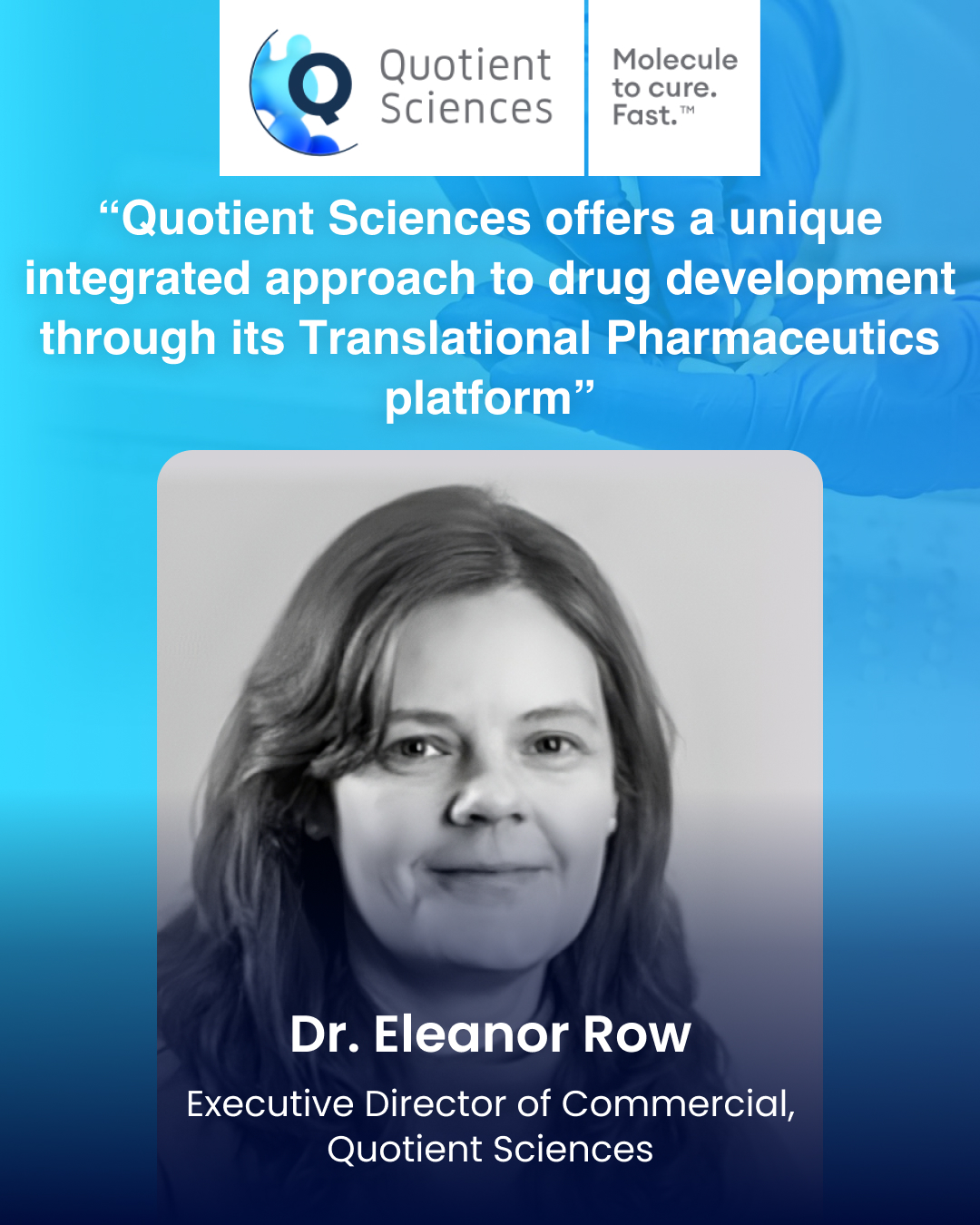

“Quotient Sciences’ integrated approach to drug development accelerates molecules to IND & beyond”

This week,

SpeakPharma interviews Eleanor Row, Executive Director of Commercial at Quotient Sciences, a global drug developmen...

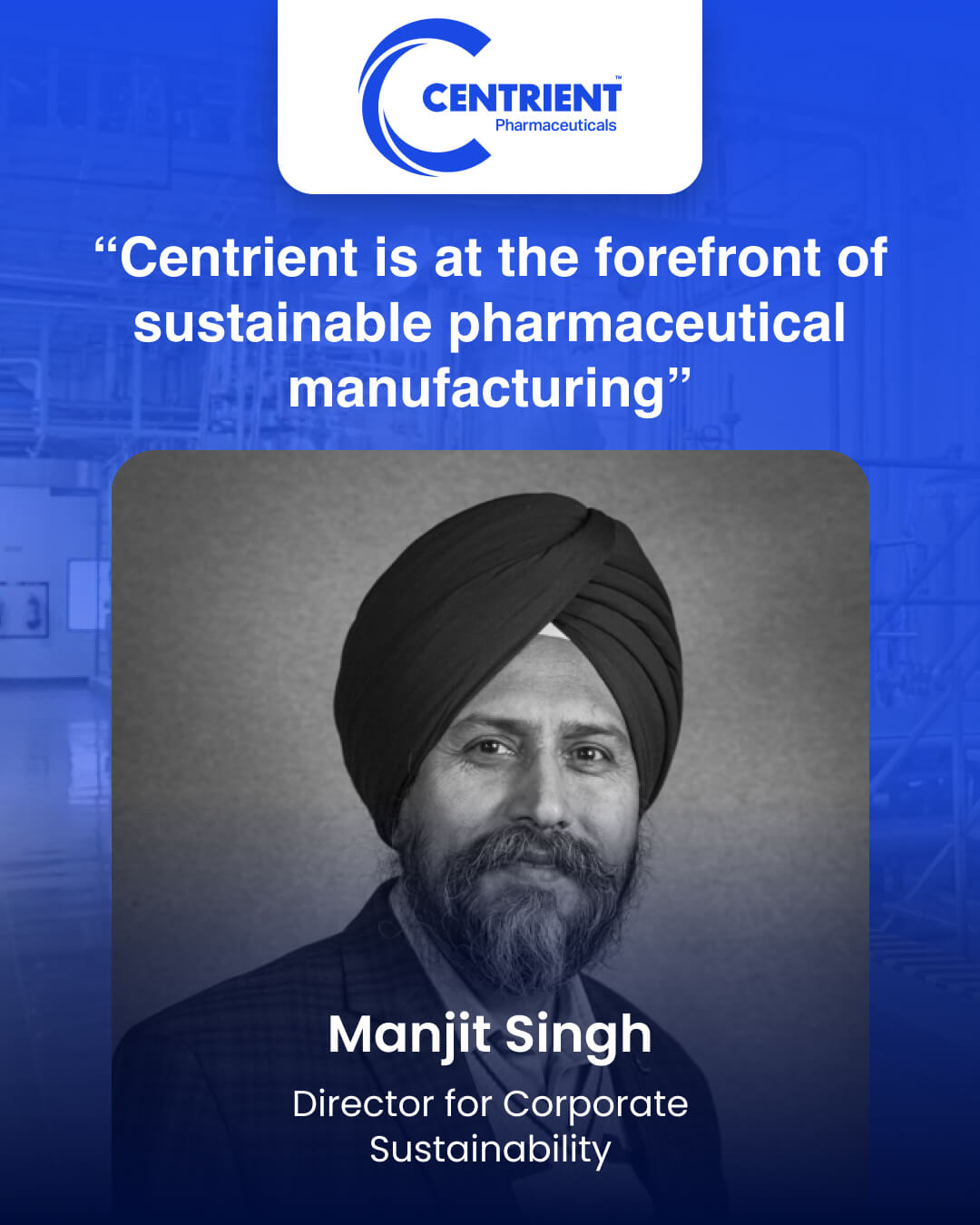

“Centrient is at the forefront of sustainable pharmaceutical manufacturing”

One of the most pressing problems today is environmental pollution. Every year, the world comes together on April 22 to ce...

“Polpharma has the best equipment and team to deliver impurity-free products”

N-nitrosamine impurities have been in the news for some years now. SpeakPharma interviewed Karina Boszko, Head of API Regulator...

Market Place

Market Place Sourcing Support

Sourcing Support