LEBSA- Your strategic API source for niche molecules.

LEBSA- Your strategic API source for niche molecules.

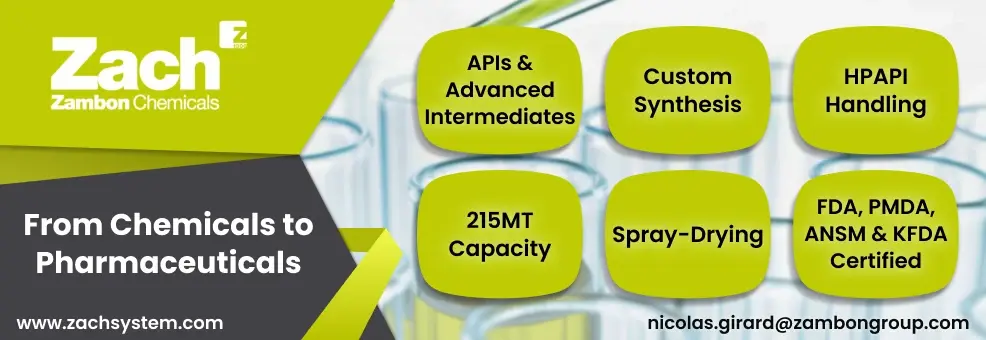

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing

Pharma Service : API Manufacturing