19 Dec 2025

// PRESS RELEASE

18 Dec 2025

// PRESS RELEASE

18 Dec 2025

// PRESS RELEASE

KEY PRODUCTS

KEY PRODUCTS KEY SERVICES

KEY SERVICES

Aspen API. More than just an API™

About

Industry Trade Show

Attending

24-26 February, 2026

BIO-Europe SpringBIO-Europe Spring

Industry Trade Show

Attending

23-25 March, 2026

Industry Trade Show

Attending

23-26 March, 2026

CONTACT DETAILS

Events

Webinars & Exhibitions

Industry Trade Show

Attending

24-26 February, 2026

BIO-Europe SpringBIO-Europe Spring

Industry Trade Show

Attending

23-25 March, 2026

Industry Trade Show

Attending

23-26 March, 2026

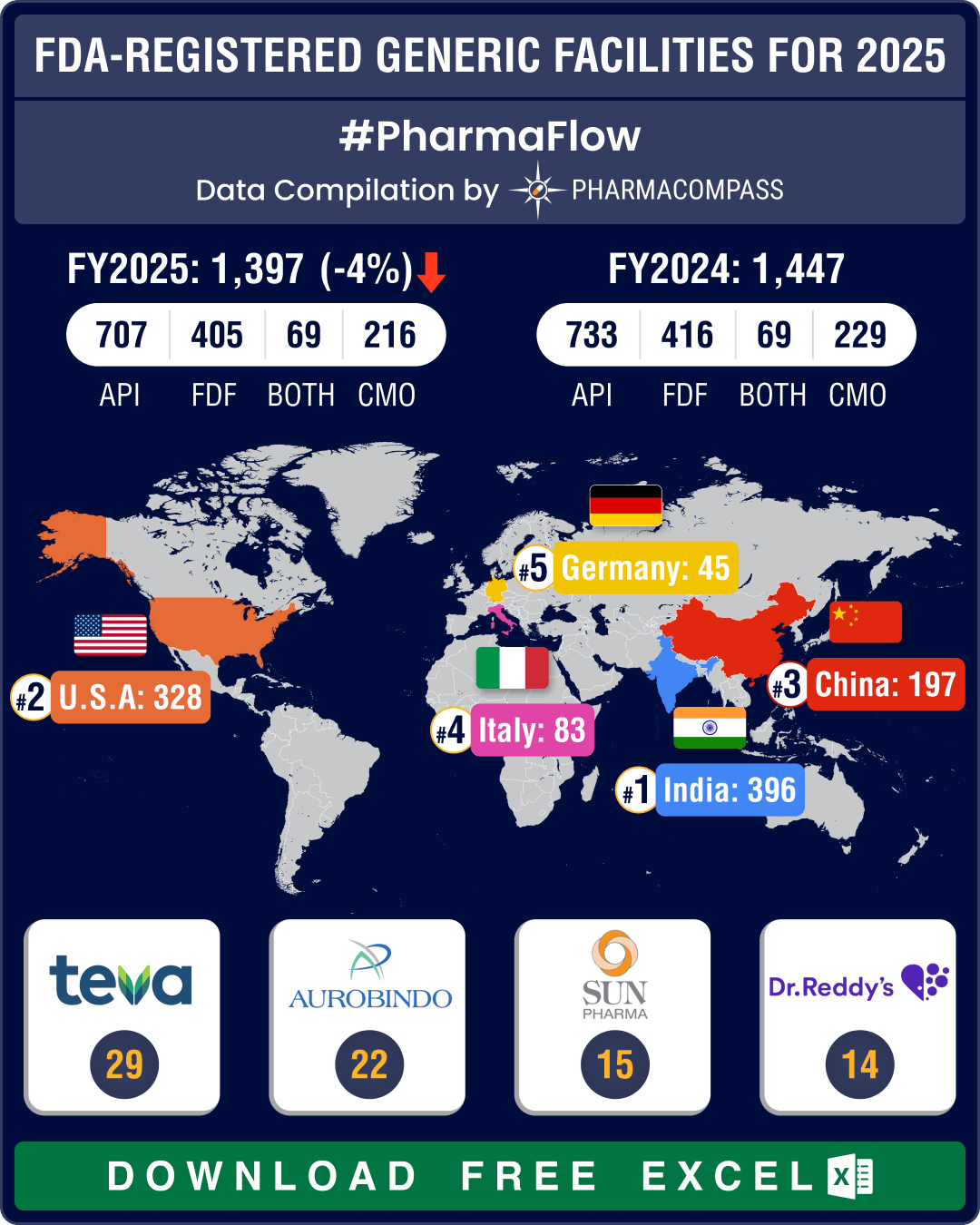

CORPORATE CONTENT #SupplierSpotlight

https://www.pharmacompass.com/radio-compass-blog/chinese-fda-registered-generic-facilities-gain-steam-india-maintains-lead-with-396-facilities

https://www.pharmacompass.com/radio-compass-blog/cdmo-activity-tracker-novo-s-parent-buys-catalent-for-us-16-5-bn-fujifilm-merck-kgaa-axplora-lonza-expand-capabilities

19 Dec 2025

// PRESS RELEASE

https://www.aspenapi.com/news/aspen-api-pioneering-sustainable-peptide-manufacturing/

18 Dec 2025

// PRESS RELEASE

https://www.aspenapi.com/news/strong-reinforcement-of-the-oss-pharma-cluster-through-the-arrival-of-aspen-oss-at-pivot-park/

18 Dec 2025

// PRESS RELEASE

https://www.aspenapi.com/news/clascoterone-and-segesterone-new-development-opportunities-in-our-aspen-api-steroid-portfolio/

30 Sep 2025

// PRESS RELEASE

https://www.aspenapi.com/news/yes-hashtagestradiol-is-added-to-our-list-of-approved-cadifas/

28 Feb 2025

// PRESS RELEASE

11 Feb 2025

// PRESS RELEASE

https://www.aspenapi.com/news/this-project-aimed-to-optimize-the-purification-process-of-desogestrel/

Services

Analytical

API Manufacturing

API & Drug Product Development

Excipients

Inspections and registrations

ABOUT THIS PAGE

Aspen API is a supplier offers 65 products (APIs, Excipients or Intermediates).

Find a price of Desogestrel bulk with DMF, CEP, JDMF offered by Aspen API

Find a price of Estradiol bulk with DMF, CEP, JDMF offered by Aspen API

Find a price of Estriol bulk with DMF, CEP, JDMF offered by Aspen API

Find a price of Ethinyl Estradiol bulk with DMF, CEP, JDMF offered by Aspen API

Find a price of Leuprolide Acetate bulk with DMF, CEP, JDMF offered by Aspen API

Find a price of Mirtazapine bulk with DMF, CEP, JDMF offered by Aspen API

Find a price of Progesterone bulk with DMF, CEP, JDMF offered by Aspen API

Find a price of Rocuronium Bromide bulk with DMF, CEP, JDMF offered by Aspen API

Find a price of Azathioprine bulk with DMF, CEP offered by Aspen API

Find a price of Estradiol Valerate bulk with DMF, CEP offered by Aspen API

Find a price of Norethisterone bulk with DMF, CEP offered by Aspen API

Find a price of Norethisterone Acetate bulk with DMF, CEP offered by Aspen API

Find a price of Oxytocin bulk with DMF, CEP offered by Aspen API

Find a price of Ropivacaine Hydrochloride bulk with DMF, CEP offered by Aspen API

Find a price of Scopolamine bulk with DMF, CEP offered by Aspen API

Find a price of Testosterone bulk with DMF, CEP offered by Aspen API

Find a price of Baclofen bulk with DMF offered by Aspen API

Find a price of Benztropine bulk with DMF offered by Aspen API

Find a price of Conjugated Estrogens bulk with DMF offered by Aspen API

Find a price of Estradiol Acetate bulk with DMF offered by Aspen API

Find a price of Estriol bulk with CEP offered by Aspen API

Find a price of Ethynodiol Diacetate bulk with DMF offered by Aspen API

Find a price of Etonogestrel bulk with DMF offered by Aspen API

Find a price of Fentanyl bulk with CEP offered by Aspen API

Find a price of Fentanyl Citrate bulk with CEP offered by Aspen API

Find a price of Fluphenazine bulk with DMF offered by Aspen API

Find a price of Fluphenazine Decanoate bulk with DMF offered by Aspen API

Find a price of Ganirelix bulk with DMF offered by Aspen API

Find a price of Gonadorelin Acetate bulk with DMF offered by Aspen API

Find a price of Human Chorionic Gonadotropin bulk with DMF offered by Aspen API

Find a price of Leuprolide Acetate bulk with CEP offered by Aspen API

Find a price of Nandrolone Decanoate bulk with DMF offered by Aspen API

Find a price of Remifentanil bulk with DMF offered by Aspen API

Find a price of Ropivacaine Hydrochloride bulk with DMF offered by Aspen API

Find a price of Testosterone bulk with CEP offered by Aspen API

Find a price of Testosterone Cypionate bulk with DMF offered by Aspen API

Find a price of Testosterone Enanthate bulk with DMF offered by Aspen API

Find a price of Testosterone Undecanoate bulk with DMF offered by Aspen API

Find a price of Thiothixene bulk with DMF offered by Aspen API

Find a price of Tibolone bulk with CEP offered by Aspen API

Find a price of Vincristine Sulfate bulk with DMF offered by Aspen API

Find a price of Cidofovir bulk offered by Aspen API

Find a price of Clascoterone bulk offered by Aspen API

Find a price of Codeine bulk offered by Aspen API

Find a price of Codeine Phosphate bulk offered by Aspen API

Find a price of Conjugated Estrogens bulk offered by Aspen API

Find a price of Difelikefalin Acetate bulk offered by Aspen API

Find a price of Dihydrotestosterone bulk offered by Aspen API

Find a price of Estradiol bulk offered by Aspen API

Find a price of Fentanyl Hydrochloride bulk offered by Aspen API

Find a price of Goserelin Acetate bulk offered by Aspen API

Find a price of Hyoscine Butyl Bromide bulk offered by Aspen API

Find a price of Lanreotide Acetate bulk offered by Aspen API

Find a price of Leuprolide Acetate bulk offered by Aspen API

Find a price of Lynestrenol bulk offered by Aspen API

Find a price of Morphine Hydrochloride bulk offered by Aspen API

Find a price of Morphine Sulfate bulk offered by Aspen API

Find a price of Morphine Tartrate bulk offered by Aspen API

Find a price of Nusinersen bulk offered by Aspen API

Find a price of Pegcetacoplan bulk offered by Aspen API

Find a price of Segesterone Acetate bulk offered by Aspen API

Find a price of Semaglutide bulk offered by Aspen API

Find a price of Sugammadex Sodium bulk offered by Aspen API

Find a price of Testosterone Propionate bulk offered by Aspen API

Find a price of Vinblastine Sulfate bulk offered by Aspen API

Aspen API

Aspen API